blown film machine parts name

Before the delivery of t. 30 Lakh Get Latest Price.

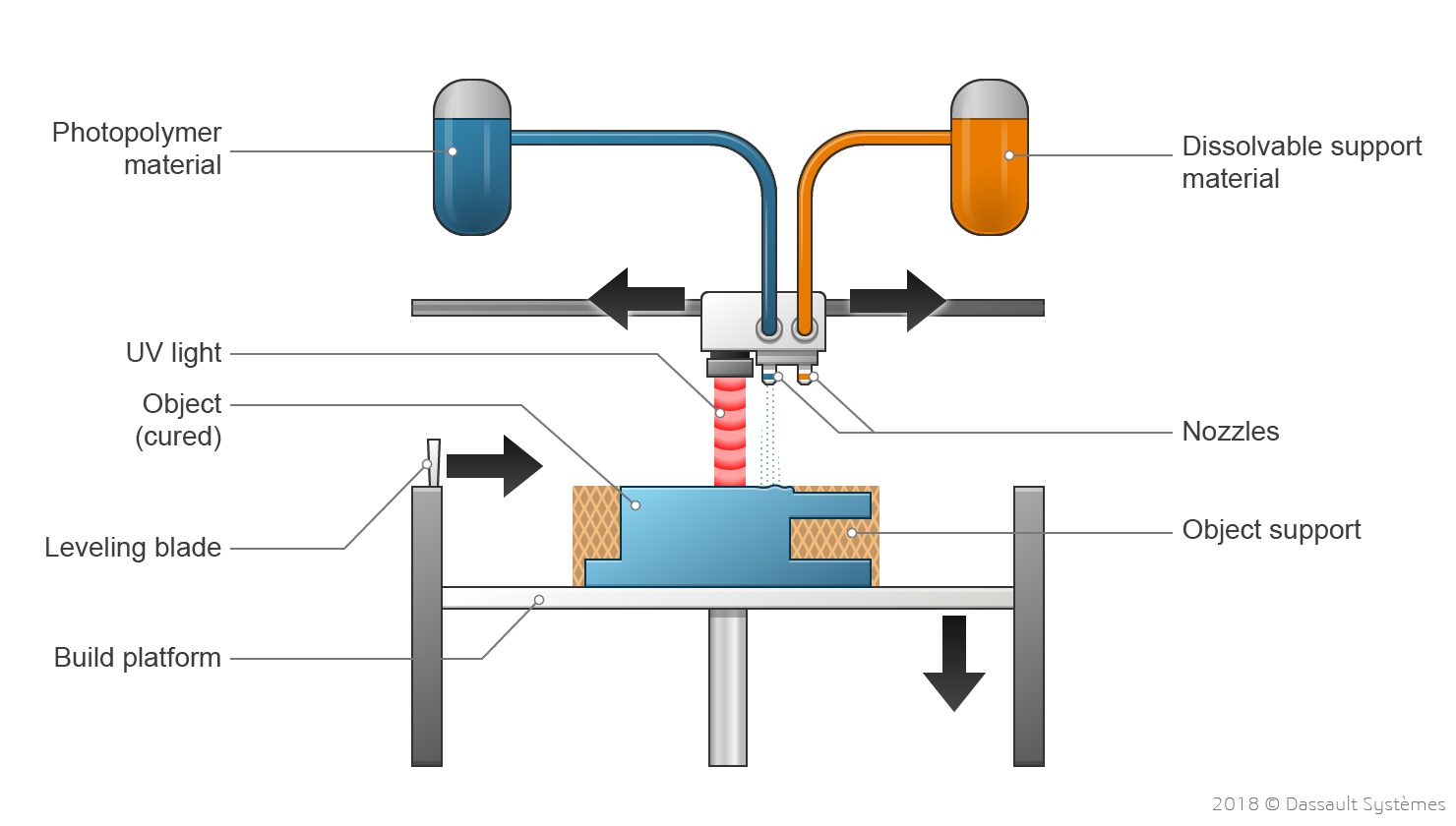

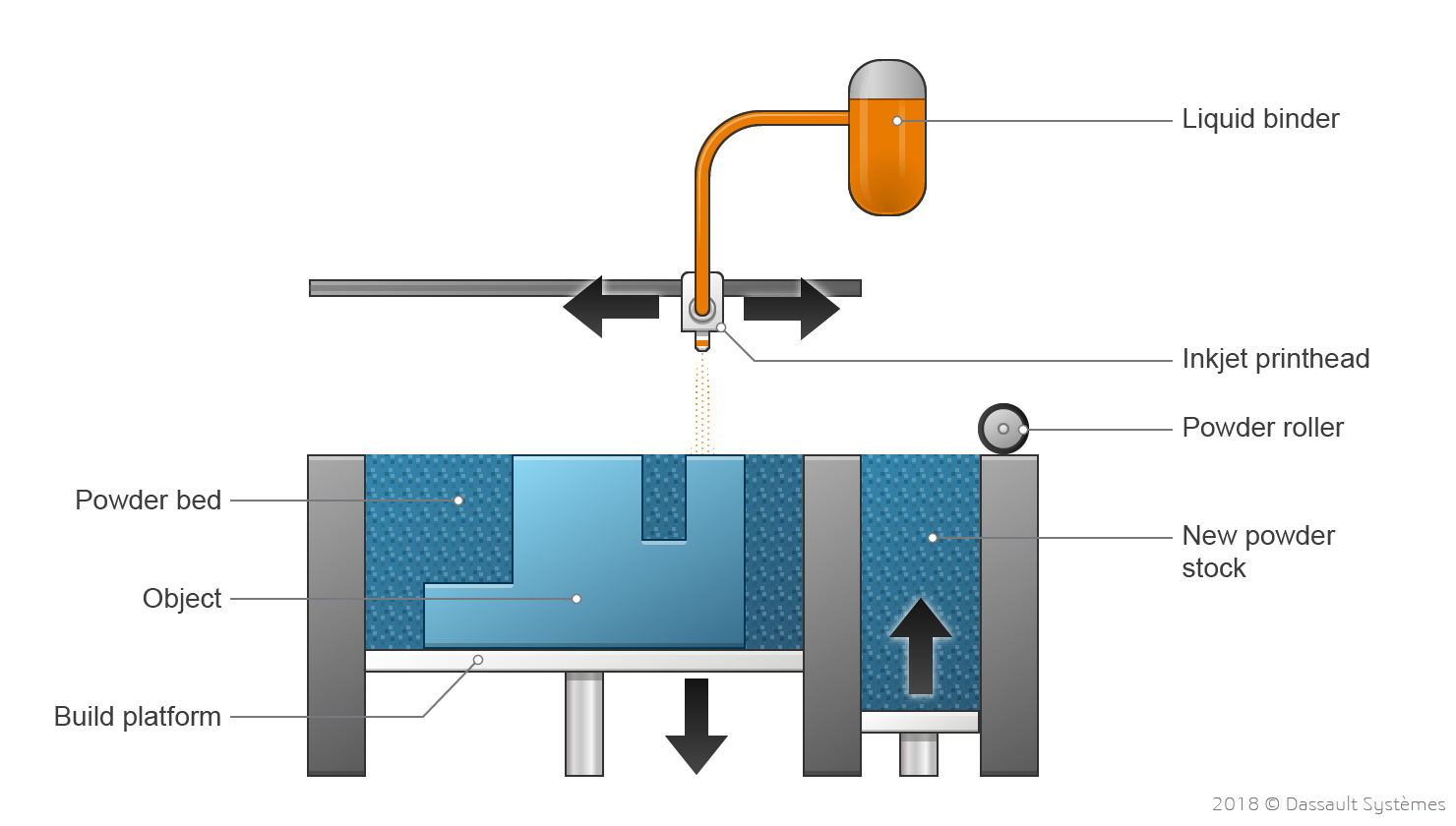

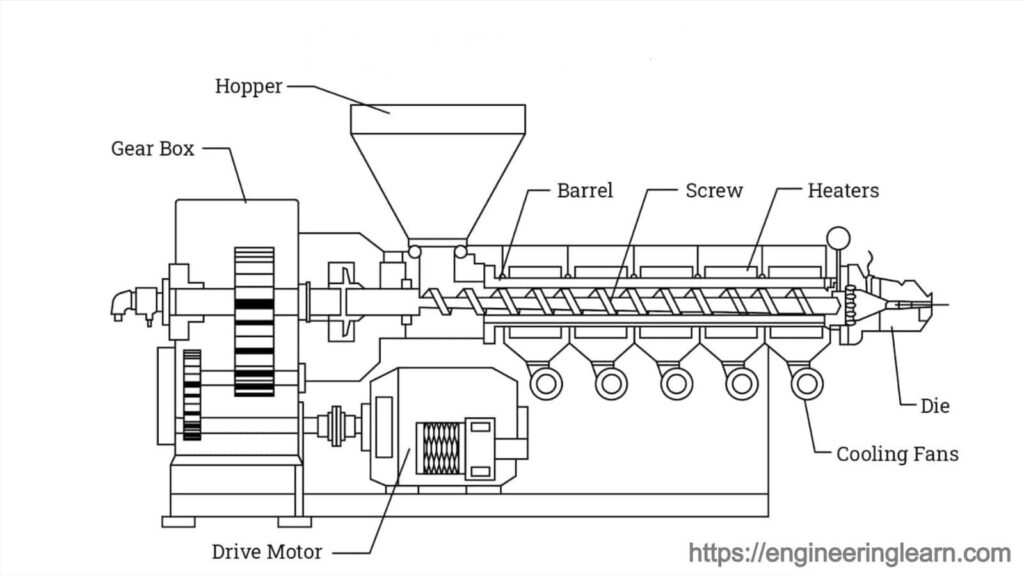

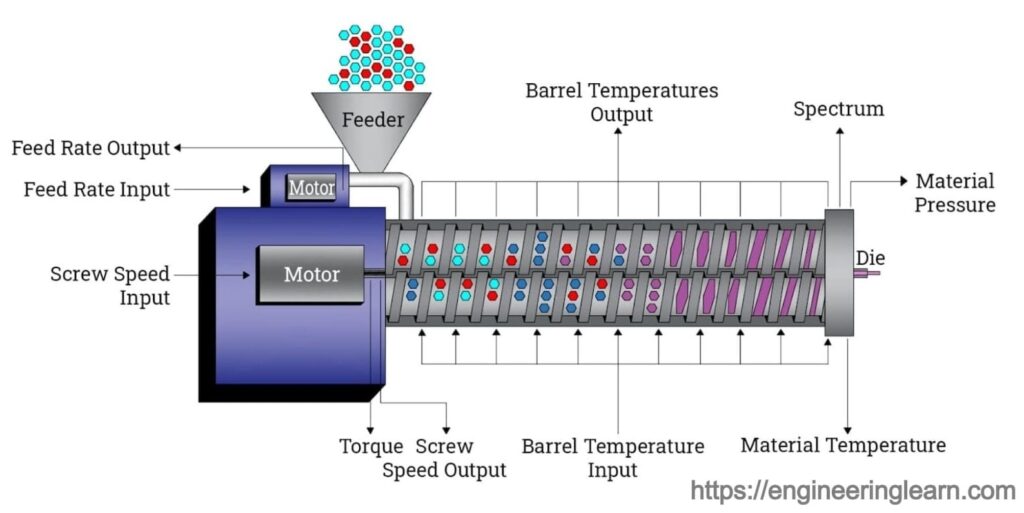

Types Of Extruders Application Working Principle Engineering Learn

Blown film extrusion can be complex so we will now explain each step of the process in detail.

. Blown film lines are used to make shrink wrap films. ISHAN Multilayer Blown Film Extrusion Machine. ABA multilayer blown film machine.

Complete tutorial of mini film blowing machines - from startup to stable operationThis is a relatively long video about 10 minutes. RUIAN DINGYI IE INDUSTRIAL CO LTD is best Film Blown Machine HDPE Blown Film Machine and LDPE Blown Film Machine supplier we has good quality products service from China. The first step is to melt the polymer in an extruder.

Two color in-line printing machine. OEM ODM Blow Molding Machine. IKV Screw is an important Yankang extrusion blow molding machine part.

WH blown film lines are designed especially for the flexible packaging industry. One layer single head blown film machine. KALINGA EXTRUSION TECHNIK - ManufacturerSupplier of Blown Film Machine from Ahmedabad Gujarat India.

Extruded tubular processing is most often used with polyethylene films but can be used with. The plastic is then. 3 Control over the angle and expansion of the main flow of air from the upper lip enabling adjustment of the low.

Blown Film Extrusion Equipment. The process of blown film is reasonably simple. Process of Blown Film Extrusion.

One layer twin head blown film machine. They are designed for highest quality. Evolution is our DNA.

Filter Default Name A-Z Name Z-A Size Small-Large Size Large-Small. Blown films provide a better balance of properties between the machine and transverse directions. A film blowing machine involves one process used to make plastic film.

2 12 Blown Film Die. Reifenhäuser blown film lines. Blown film lines require.

The name EVO stands for blown film lines of the latest generation which have one thing in common. We are producing blown film lines since 1967 and have consistently set new standards such as the. The two pairs of traction rollers are composed of a rubber roller and a steel roller which can effectively prevent gas from escaping and ensure the coil material.

SS Mechanical Engineers Pvt. What is Blown film Extrusion process in Hindi Blow ratio Draw Down Ratio PlasticsWorld alokrj cipet This video is for BTech BSc CIPET students. Ruian Hendin Machinery COLTD ADDPandai Industrial ZoneRuian CityZhejiangChina WhatAppWechat.

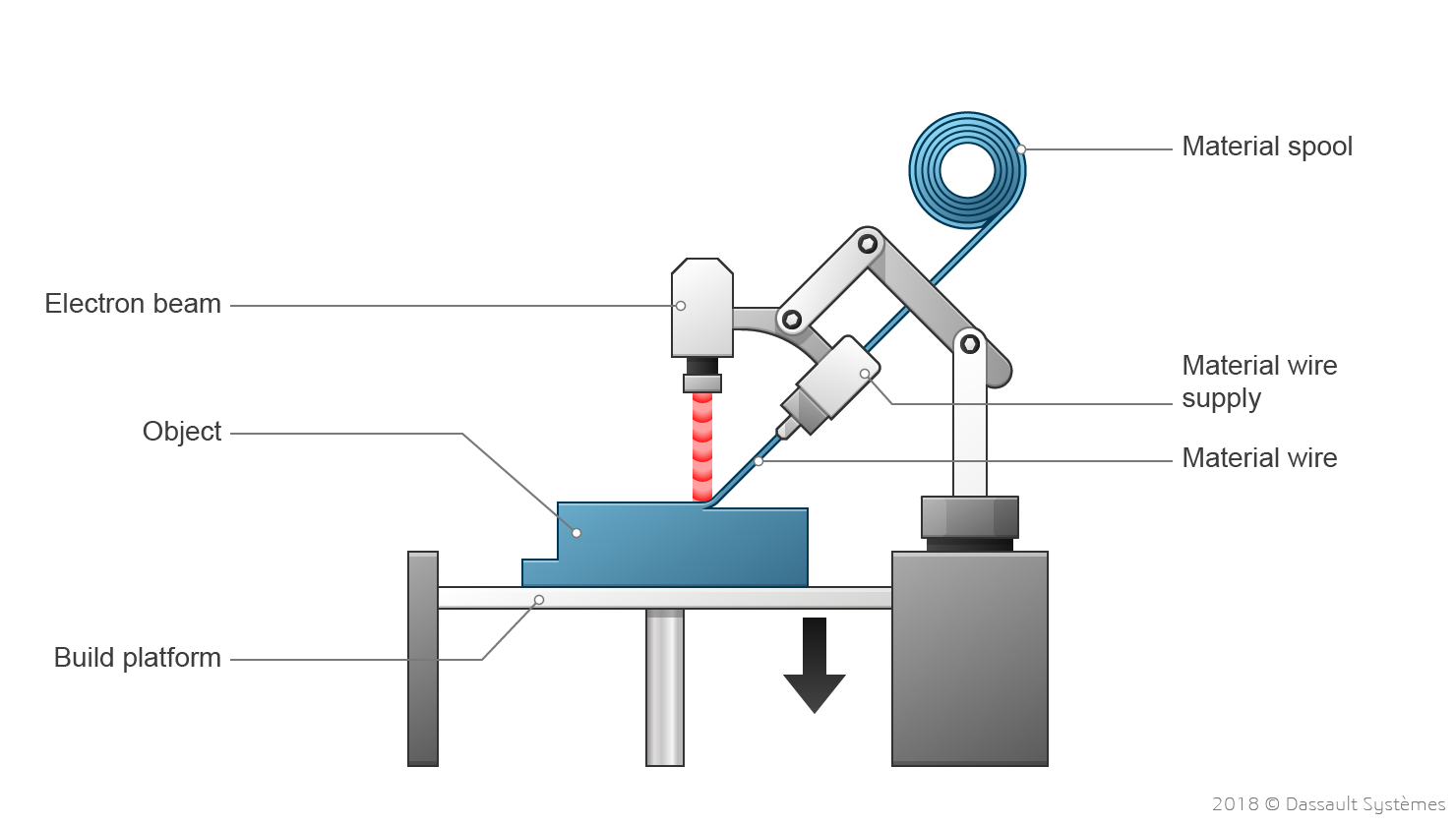

The blown film is produced by using an extruder that incorporates a blown film die and a cooling tower to cool the bubble. Home Machine Spare Parts Blowing Machine Spare Parts. 2 A suitable expansion angle leading to the upper lip and.

Blown film extrusion equipment is used in hundreds of industries around the world. Blowing Machine Spare Parts bravan2 2022-04-28T0741540000. First step plastic pellets are put into the extruder and heated to their melting point at 180 to 210 Celcius degree.

5 Layer Blown Film Co-ex Line Highly versatile die design leading to optimum quality of Barrier as well as Facilitates optimisation of Tie Layer Blown Film Co-extrusion Lines In Technical. 15 Davis Standard Blown Film Tower Model BTF. The components of the co-extrusion blown film line are.

Compared with a traditional screws the plasticizing efficiency is increased by 15 times and the.

Blown Film An Overview Sciencedirect Topics

Extruders An Overview Sciencedirect Topics

Extrusion An Overview Sciencedirect Topics

Types Of Extruders Application Working Principle Engineering Learn

Blown Film Bandera Plastics Extrusion Italy

Tutorial Injection Molded Parts

Single Screw Extruder An Overview Sciencedirect Topics

Extrusion Design Dies Tooling Aec